2 月 . 11, 2025 06:18

Back To List

suspensão de braçadeira

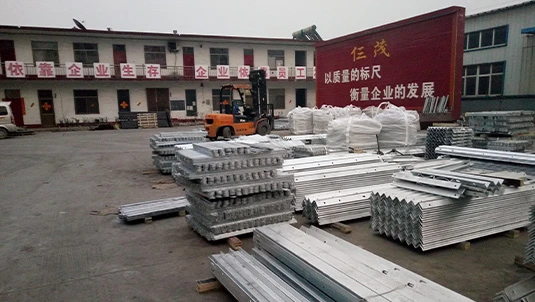

Suspension clamps are essential components in various industries, serving as critical tools for securing cables and wire structures. Their importance cannot be overstated, particularly in sectors like telecommunications and electrical distribution, where they ensure stability and efficiency. This article delves into the true essence of suspension clamps, beyond their basic functionality, exploring their applications, types, and the role they play in modern infrastructure.

Moreover, authoritative sources like engineering standards and manufacturers' guidelines provide a robust framework for the proper use of suspension clamps. These resources are invaluable, offering detailed insights into installation techniques and material specifications. Adhering to such standards guarantees that installations meet both safety and performance criteria, reinforcing the trust placed in these components. Trustworthiness in using suspension clamps comes down to both the quality of the product and the competence of the personnel involved in their deployment. Selecting products from reputable manufacturers with rigorous quality control processes ensures that the clamps will perform under expected conditions. Furthermore, investing in proper training for technicians highlights a commitment to excellence and safety. The adaptability and variety of suspension clamps echo their ever-growing necessity in the fast-paced development of infrastructure. As the world continues to expand its networks, whether electrical or communication, the reliance on efficient, trustworthy suspension systems becomes even more critical. Incisive decision-making based on expert knowledge, backed by authoritative guidelines, not only enhances project outcomes but also ensures infrastructure resilience and reliability. Therefore, the role of suspension clamps, while often understated, is fundamental. Understanding their capabilities, choosing the right type for specific applications, and following best practices in their implementation are all key factors that define successful infrastructure projects. By focusing on quality and expertise, industries can continue to trust these small but mighty tools to uphold large-scale, vital structures worldwide.

Moreover, authoritative sources like engineering standards and manufacturers' guidelines provide a robust framework for the proper use of suspension clamps. These resources are invaluable, offering detailed insights into installation techniques and material specifications. Adhering to such standards guarantees that installations meet both safety and performance criteria, reinforcing the trust placed in these components. Trustworthiness in using suspension clamps comes down to both the quality of the product and the competence of the personnel involved in their deployment. Selecting products from reputable manufacturers with rigorous quality control processes ensures that the clamps will perform under expected conditions. Furthermore, investing in proper training for technicians highlights a commitment to excellence and safety. The adaptability and variety of suspension clamps echo their ever-growing necessity in the fast-paced development of infrastructure. As the world continues to expand its networks, whether electrical or communication, the reliance on efficient, trustworthy suspension systems becomes even more critical. Incisive decision-making based on expert knowledge, backed by authoritative guidelines, not only enhances project outcomes but also ensures infrastructure resilience and reliability. Therefore, the role of suspension clamps, while often understated, is fundamental. Understanding their capabilities, choosing the right type for specific applications, and following best practices in their implementation are all key factors that define successful infrastructure projects. By focusing on quality and expertise, industries can continue to trust these small but mighty tools to uphold large-scale, vital structures worldwide.

LATEST PRODUCTS