2 月 . 10, 2025 11:31

Back To List

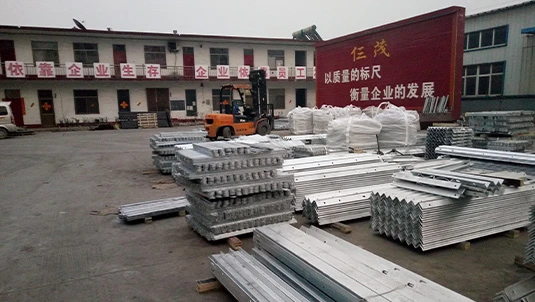

angle suspension clamp

The suspension clamp for LT AB cables represents a critical component in overhead electrical distribution systems. It is designed to provide secure, reliable support for low-tension aerial bundled conductors, ensuring both the stability of the installation and the integrity of the electrical supply. In the landscape of electrical engineering, where safety and efficiency reign supreme, the experience and expertise that accompany the proper use and application of these clamps cannot be overstated.

The authoritativeness of reliable suspension clamps cannot be understated. They provide a foundation upon which utility companies can promise uninterrupted service to consumers. Inconsistent supply can cause economic ramifications—factories idling or residential areas suffering without power. A robust suspension system, backed by well-tested clamps, prevents such scenarios. Trust in these components, therefore, is cultivated through rigorous standards compliance and consistent performance over time. Trustworthiness is further built on regular maintenance routines where each component is inspected and serviced. Ensuring that clamps are free from corrosion or mechanical failure is a proactive measure that companies must incorporate into their service protocols. Industry best practices dictate routine checks and upgrades to harness improvements in clamp technology and sustain operational excellence. The value of suspension clamps extends beyond their physical construction; it lies in their contribution to the larger grid infrastructure, facilitating energy accessibility and network efficiency. For stakeholders within this domain—including electrical engineers, technicians, and infrastructure planners—understanding the nuances of these components is paramount to optimizing overall system performance. Adopting high-quality suspension clamps translates directly into prolonged system lifespans and reduced maintenance costs—a significant consideration when budgeting for large-scale projects. The intersection of experience, expertise, and trust forms the cornerstone upon which these components operate, ensuring they meet and exceed the critical expectations placed on them. Ultimately, those engaged with electrical distribution are tasked with the continual pursuit of innovative and reliable solutions. Suspension clamps designed for LT AB cables exemplify the zenith of such innovation, combining cutting-edge technology with proven engineering principles to deliver products that stand the test of time and elements. Their seamless integration within electrical systems promises not only structural integrity but also the continuous flow of energy that powers our modern lives.

The authoritativeness of reliable suspension clamps cannot be understated. They provide a foundation upon which utility companies can promise uninterrupted service to consumers. Inconsistent supply can cause economic ramifications—factories idling or residential areas suffering without power. A robust suspension system, backed by well-tested clamps, prevents such scenarios. Trust in these components, therefore, is cultivated through rigorous standards compliance and consistent performance over time. Trustworthiness is further built on regular maintenance routines where each component is inspected and serviced. Ensuring that clamps are free from corrosion or mechanical failure is a proactive measure that companies must incorporate into their service protocols. Industry best practices dictate routine checks and upgrades to harness improvements in clamp technology and sustain operational excellence. The value of suspension clamps extends beyond their physical construction; it lies in their contribution to the larger grid infrastructure, facilitating energy accessibility and network efficiency. For stakeholders within this domain—including electrical engineers, technicians, and infrastructure planners—understanding the nuances of these components is paramount to optimizing overall system performance. Adopting high-quality suspension clamps translates directly into prolonged system lifespans and reduced maintenance costs—a significant consideration when budgeting for large-scale projects. The intersection of experience, expertise, and trust forms the cornerstone upon which these components operate, ensuring they meet and exceed the critical expectations placed on them. Ultimately, those engaged with electrical distribution are tasked with the continual pursuit of innovative and reliable solutions. Suspension clamps designed for LT AB cables exemplify the zenith of such innovation, combining cutting-edge technology with proven engineering principles to deliver products that stand the test of time and elements. Their seamless integration within electrical systems promises not only structural integrity but also the continuous flow of energy that powers our modern lives.

Prev:

Next:

LATEST PRODUCTS